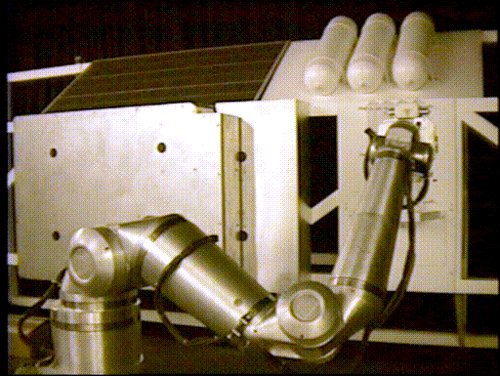

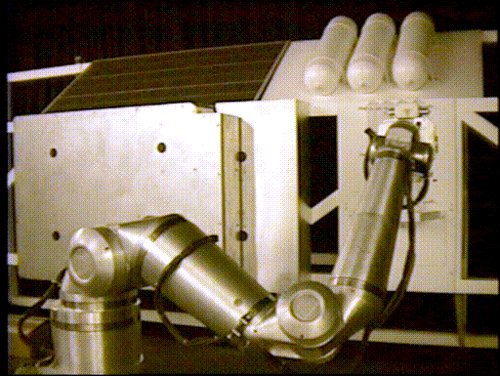

A scaled space station truss mockup is inspected by a seven degrees-of-freedom robot arm carrying the ISEE sensor payload.

During the planned thirty year lifetime of NASA's Space Station Freedom, significant surface damage is expected from micro-meteorite impacts, atomic oxygen degradation, and other effects. Since continual direct astronaut inspection of the station is not feasible, NASA has been investigating telerobotic methods with a prototype inspection system developed by the Remote Surface Inspection research task at the Jet Propulsion Laboratory, California Institute of Technology. The inspection system is comprised of three subsystems: robot manipulation, graphical user interface and multi-sensor inspection. The manipulator is a Robotics Research K1207 arm mounted on a translating platform. The user interface resides on a graphics workstation and provides user-friendly interfaces to the manipulator control and the inspection data. The multi-sensor inspection subsystem gathers and analyzes data from a realistic Space Station mockup under simulated orbital conditions.

Central to the multi-sensor inspection is the compact (3.5 kg) Integrated Sensor End Effector (ISEE). The ISEE has two cameras and illuminators needed for visual inspection, as well as a suite of other sensors to detect temperature, gas/vapors, eddy-currents, proximity, and force. The CCD color cameras are aligned for human stereo-scopic viewing and the color images are displayed in stereo at the workstation. The machine vision system uses the luminance of the video signal to perform automatic flaw detection by reference image differencing. The continuous illuminators are maintained at a known illumination level by an optical transistor feedback circuit. This is augmented by strobe illuminators that provide lighting comparable to solar illumination (when the cameras are electronically shuttered to 1/10000 s) but only for short, energy saving, single camera frame bursts. Temperature sensing is achieved with an infrared optical pyrometer (8-12 micron wavelength), sensitive to temperatures from 0 to 1000 deg F. Gas sensing is achieved with a metal oxide semiconductor sensor, in lieu of a mass spectrometer which requires the ambient vacuum of space. Eddy-current sensing is used to detect minute cracks in the Space Station mockup structure. Proximity and force detection aid the other inspection techniques and provide collision prevention and contact force control. Parallel jaw grippers are also available to hold sensors and open compartments on the Space Station.