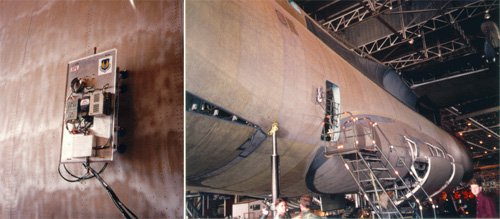

The MACS system being tested on a large military aircraft.

A novel multifunction automated crawling system (MACS) has been designed and fabricated to carry miniature instrumentation to perform a wide variety of inspection tasks while attached to the surface of the structure of interest. The immediate application of MACS is aircraft inspection and various inspection modules can be used for this purpose. MACS employs ultrasonic motors for mobility and suction cups for surface adherence. MACS has two legs for linear motion and a rotation element for turning, enabling any simultaneous combination of motion from linear to rotation about a central axis. The use of ultrasonic motors, composite materials construction, miniature computer and video cameras enables a small, light weight crawling system with an effective carrying capability ratio of about 1:10. MACS I is 11x19 inches. A new design, MACS II, is 10x10 inch.

Application

The initial target application is inspection of the exterior of the C-5 aircraft. Currently there are large areas of the aircraft which are difficult to reach by a person due to being very high up on the aircraft such as the upper areas of the fuselage and the tail section. The MACS crawler will be able to crawl on these areas and perform the inspection. MACS will send images and sensor data back to an operator who could be at the base of the aircraft, in a local control room, or potentially anywhere in the world.

NASA Technology Leveraging

Development of the MACS crawler has benefited from leveraging ongoing NASA miniature planetary rover, telerobotics, and NDI technology development. The leveraged technologies include the miniature and lightweight mechanisms, on-board computing and intelligence, and miniature sensors.

Unique Mechanism Design

The MACS crawler has a unique mechanical design to overcome previous crawler design limitations. The mobility of MACS is performed with compact, light weight ultrasonic motors. Two motors simultaneously provide the linear motion and a single motor provides the rotation. The rotation motor is connected to the inner leg of the crawler and it is installed vertically over the crawler platform. A set of short profile vacuum cups were specially designed for MACS to allow its adherence to the surface while moving. To control the operation of MACS and perform such tasks as imaging, data acquisition, and communication, a miniature on-board computer is used. The MACS II crawler will have the same mobility characteristics, but using only two motors - one for linear motion and one for rotational motion.