Robotic sample acquisition and handling has been an integral part of several Mars missions and will be an important capability in future missions.

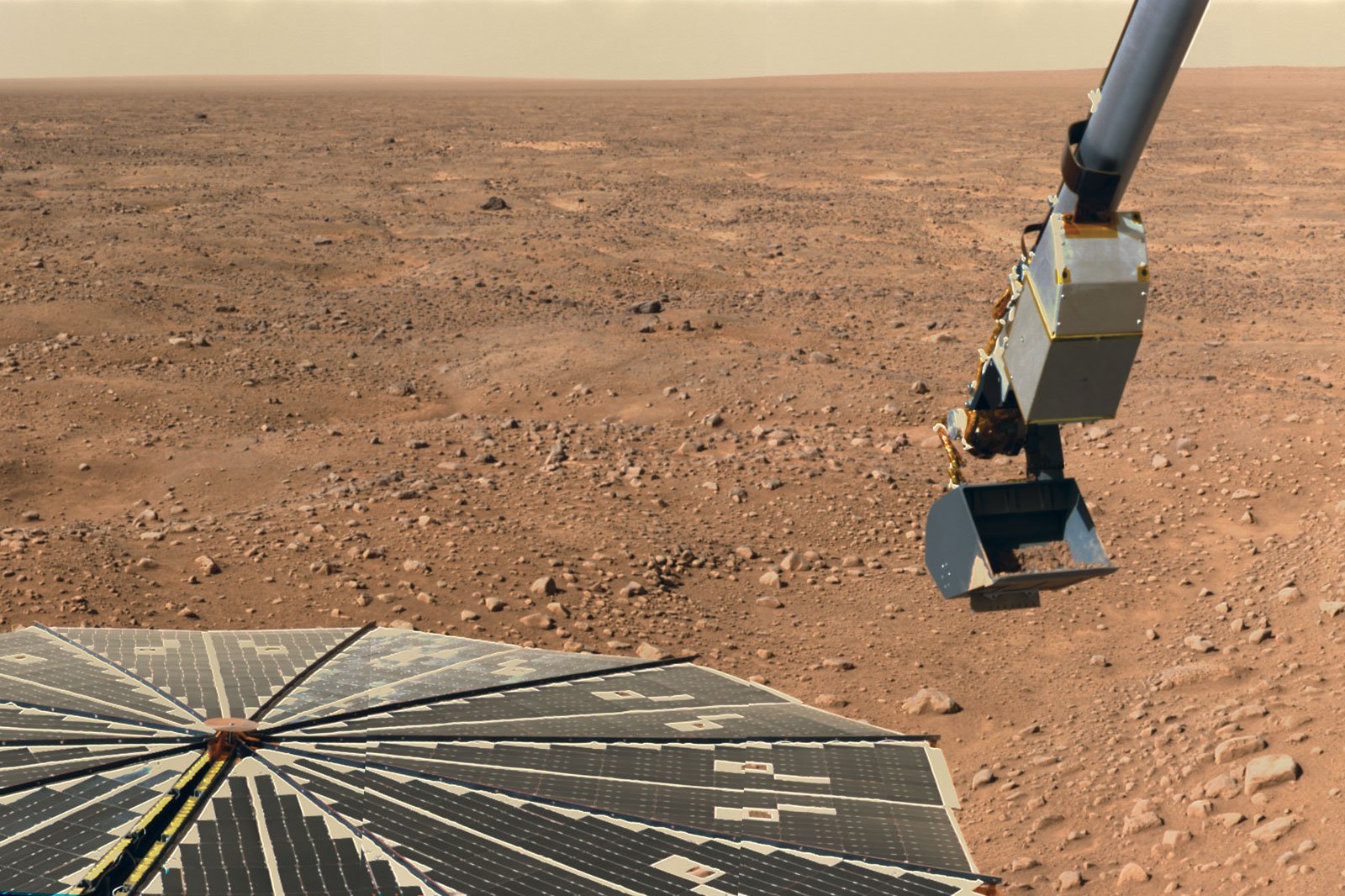

The Phoenix lander touched-down in the icy northern polar region of Mars on May 25, 2008. Robotics technology was developed and integrated into the lander system to enable it to dig trenches up to a half-meter deep in layers of frozen soil, scoop samples, and transfer the samples to lander-mounted instruments. Technical challenges arose from the need for autonomous digging in unknown soil with limited sensory information. Automated obstacle detection and recovery actions were integrated with the digging algorithms. A scoop on a four degree-of-freedom robotic arm removed material from above an icy layer and then a rasp integrated into the back of the scoop acquired strong icy material which collected in the scoop and was subsequently dropped into an instrument for analysis.

Surface material collected in the Phoenix scoop.

Trench dug by the Phoenix scoop exposing an icy layer.

The Mars Science Laboratory mission rover landed on Mars in October 2011. A robotic manipulator arm carried science instruments, a sample-acquisition scoop, and a coring tool. Robotics technology enabled the manipulator to deploy the drill to acquire samples and distribute them to various science instruments mounted on the rover body. Large interaction forces between the coring tool and rock caused technical challenges in the robotic coring operation.

Artistic concept of Mars Science Laboratory rover on Mars.

MSL drill acquiring a sample on Mars.

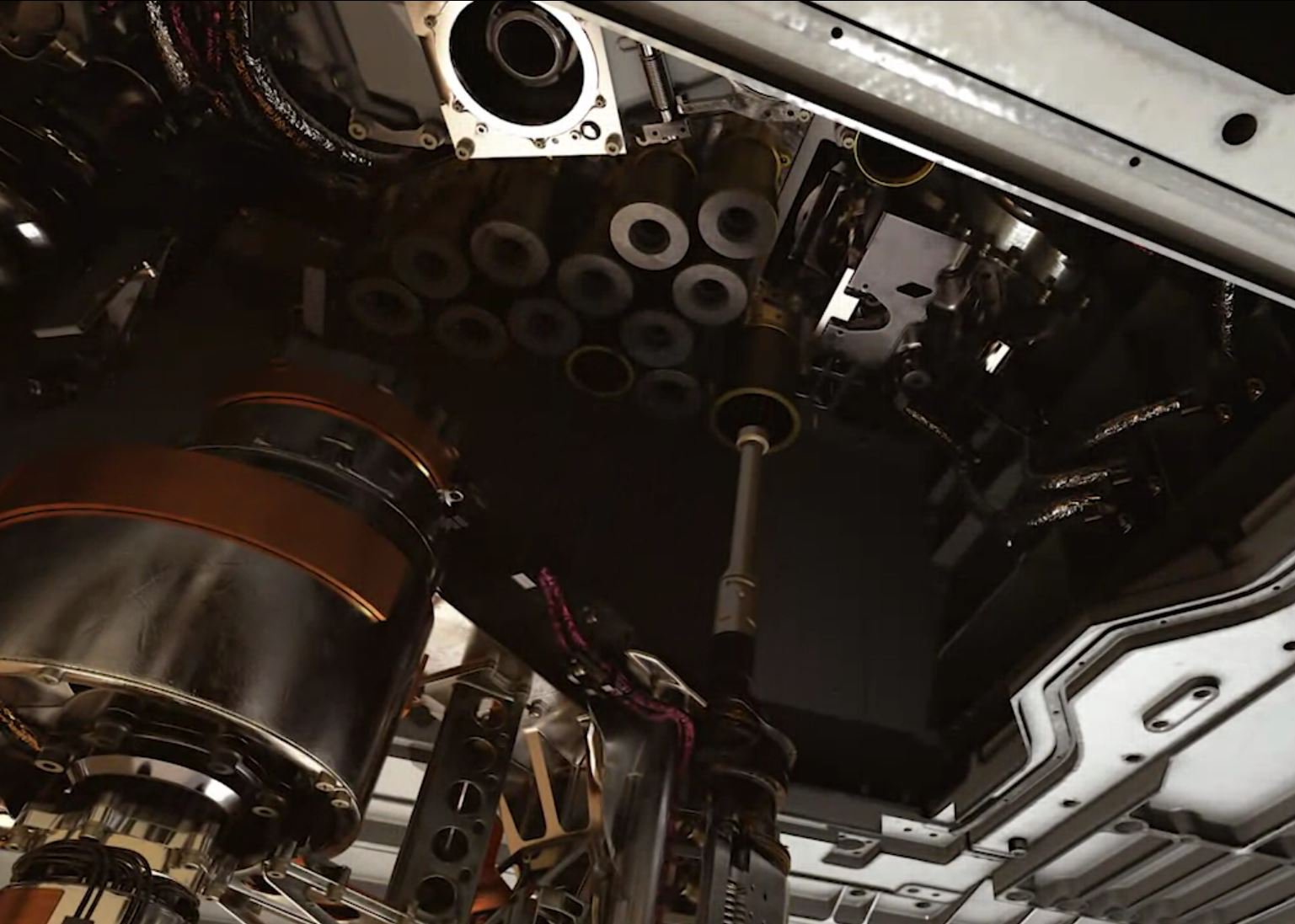

The Mars 2020 mission is acquiring core samples and storing them in individual hermetically sealed sample tubes as the first in the series of Mars Sample Return (MSR) campaign missions. The MSR campaign has the overall objective of eventually returning the core samples to Earth. The M2020 rover has a coring drill at the end of the five degree-of-freedom robotic arm which acquires a core sample directly into a sample tube in the coring bit. The bit is docked and released onto the rover and the sample tube with core sample is removed from the bit using a second high precision robotic sample handling arm. The sample is inspected inside of the tube and the tube is hermetically sealed and stored in the rover. An empty tube is then inserted into the coring bit which is then reattached to the coring tool for enable acquisition of another sample. It is anticipated that the rover will transfer the sample tubes to a future MSR Sample Return Lander mission lander after rendezvousing with it. Many challenges were overcome to develop the Sampling and Caching Subsystem (SCS) for the M2020 mission. The novel architecture of inserting the sample tube into the bit after the bit was released onto the rover was invented. This enabled handling of the sample tube rather than the core for robust sample handling. Stringent contamination control requirements added significant challenge in the design and deployment of the sampling system.

Artistic concept of the Mars 2020 rover acquiring a core sample.

The Mars Sample Return Lander mission is under development with objective of receiving the sample tubes from the Mars 2020 rover and launching them into orbit around Mars for eventual return to Earth. Robotics challenges include docking and transferring the sample tubes from the Mars 2020 rover and inserting the tubes into the closely packed Orbiting Sample (OS) container. The OS would be launched through the Mars atmosphere and released into orbit by the Mars Ascent Vehicle.

Mars 2020 internal Sample Handling Arm manipulating a sample tube at the inspection station.

Artist concept of the Mars Ascent Vehicle launching the core samples off of Mars, then to be released into passive orbit around Mars before being returned to Earth.

The BiBlade sampling system was developed for a potential future comet surface sample return mission. In the touch-and-go mission concept, a spacecraft would descend to the comet surface with the BiBlade deployed at the end of a robotic arm. Upon contact with the surface, two blades would be driven into the surface with strong springs to capture and contain the sample while the spacecraft thrusts away from the surface. After reaching a safe distance from the comet, the robotic arm would insert the sample contained between the blades into a sample container and the blades would be retracted to leave the sample in the sample container. A lid would be released from the front of the BiBlade tool to enclose the sample in the container that is in the Sample Return Capsule (SRC). The spacecraft would return the SRC to Earth and release it to then fall to the Earth’s surface to enable recovery of the samples.

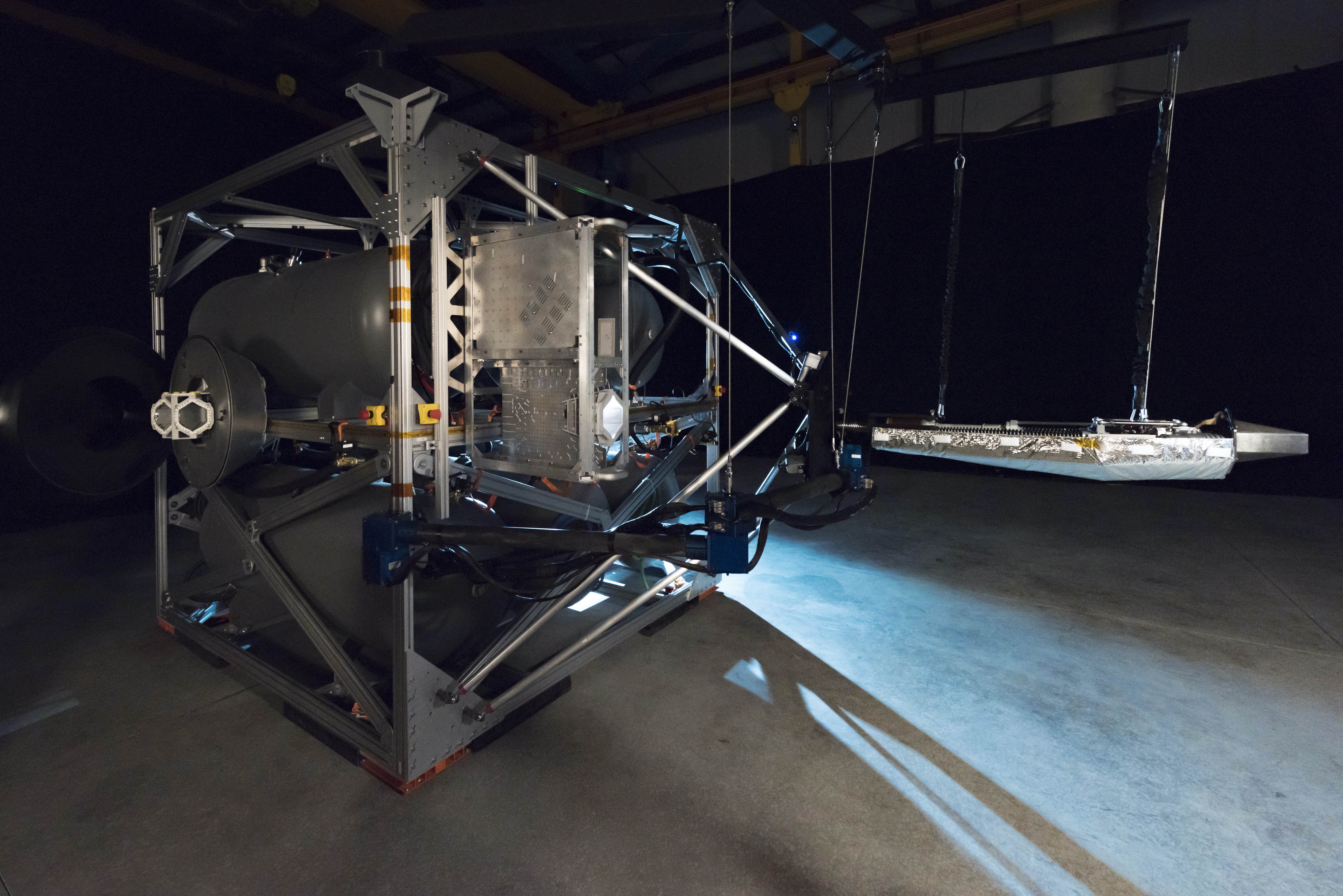

Validation testing of the BiBlade sampling system on a full-scale air-levitated 2200kg spacecraft emulator.

Missions to our solar system’s ocean worlds such as Jupiter’s moon Europa or Saturn’s moon Enceladus will rely on increased on-board autonomy due to the large transmission times and low bandwidth of communication. Autonomy for robotic sampling is being developed to enable sampling without need for human-in-the-loop perception and planning. This includes automated terrain analysis, sampling target selection, estimation of tool-terrain interaction models, and intelligent sampling behaviors to adjust operation based on the state of progress.

A sampling system was developed for a potential future landed mission to Saturn’s moon Enceladus. Enceladus has plumes in the southern region that continuously eject material from the subsurface liquid water ocean, some of which falls and accumulates on the surface. The Enceladus surface environment presents unique challenges for a sampling system including low 1% of Earth’s gravity, cryogenic temperatures, vacuum, and large range of potential surface sampling material to sample. The Dual-Rasp sampling system has two rasp-like counter-rotating cutters that acquire and throw surface material up between them and which then follows a guide into a sample cup in the tool. A two degree-of-freedom manipulator would deploy the tool to the surface to enable sampling across an arc in front of the lander for minimized system complexity while acquiring ample sample volume. Pneumatic sample transfer is used to carry the cuttings from the tool through a tube along the arm and to science instruments on the lander. Sampling and sample transfer were validated in thermal vacuum chamber and system level testbeds.